History

Tecnova HT:

Pioneering manufacturing process control in Milan

Founded in a modest Milan basement in 1974 by the Cavalli brothers, Tecnova HT set out to revolutionize production process control with electro-instrumental solutions.

From day one, it wasn’t just about instruments—it was about hard work (“so much black under the nails”) and unwavering inner motivation that still drives us to charter a plane just to deliver a single spare part and help our customers meet their professional challenges.

Originally serving Naval and Oil & Gas clients with flow measurement, our unwavering vision has always been to deliver top-tier solutions for controlling production processes, backed by proactive, high-quality customer service.

Few remember when in the pioneering 80s we went to Customers with a suitcase explaining that it was possible to measure the flow rate of a liquid outside the tube: no one believed it, in fact they were the first innovative applications developed with the clamp-on ultrasonic technology of Fuji Electric Co., Ltd.. The control of production processes was taking its first concrete steps.

DPU Differential Pressure Switch Original Barton Instruments

The first fully instrumented and interconnected plant

– Clamp-On Ultrasonic Technology: In the early 1980s, we traveled with a suitcase to demonstrate non-invasive flow measurement using Fuji Electric’s clamp-on ultrasonic solutions—one of the first concrete steps in controlling production processes without interrupting operations.

– Differential Pressure Switches: Our DPU series from Barton Instruments offered precise pressure monitoring, reinforcing our reputation in manufacturing process control.

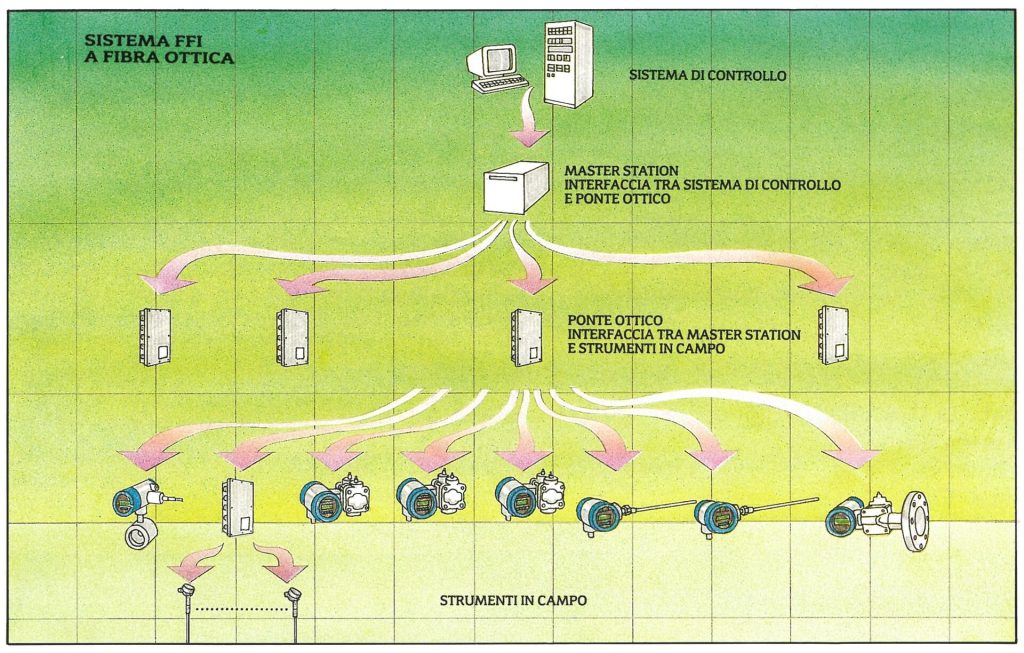

– Fiber-Optic Interconnected Plant: Over 40 years ago, when pneumatics still reigned, Tecnova HT delivered the first fully instrumented, fiber-optic interconnected production plant—truly science fiction at the time, made possible by our most powerful asset: Customer Trust.

Yes, we were in the future of production process control already 40 years ago…

Mutual Trust: The Foundation of Our Model

Because you see, Mutual Trust is the prime mover that supports the complex relational system at the base of Tecnova’s business model…

Mutual trust fuels every project. Take our 50-year partnership with VAF Instruments as an example: from the first PD meters in the 1970s to today’s cutting-edge Shaft Power Limitation technology for naval efficiency, our collaboration embodies the strengths of effective manufacturing process control.

It is always Trust that makes our Service Team a welcome guest for Field Operators: in addition to the always first-rate technical equipment, its recognized Value is the Competence that is achieved and developed through a continuous Training Program, as per ISO 9001, including both technical aspects, such as maintenance procedures, and regulatory aspects relating, for example, to CEMS systems for stack emissions.

“Bro, I love a job well done…”

Our motto, ensuring every aspect of controlling production processes meets exacting standards

Why do we believe so much in Training? Because it is precisely the women and men who commit themselves every day in TECNOVA HT who represent the most important corporate asset in which we have always invested for five decades: you should know that each of your single orders or interventions in your plant is managed by a close-knit Team that is the result of a wise mix of decades of experience and new, fresh, unconventional ideas

“Because new things are only done with young people. Only young people throw themselves into it with enthusiasm, and collaborate in harmony without personalisms and without the obstacles deriving from a customary mentality” – Mario Tchou, the genius of Olivetti [1]

Control of production processes for efficiency, safety, sustainability

Now from 2024 our working group is expected to face new and increasingly difficult challenges: we would like to improve your production efficiency, increase the safety of your personnel and contribute to a real sustainability of your plants thanks to our knowledge, our creativity and our commitment. We will not disappoint you this time either: it is our solemn promise. Because the control of production processes has always been part of our DNA.

Up/downstream control of chromatographic separation by concentration, conductivity, pH and temperature

Celebrating 50 Years of Excellence

These are our roots, this is our belief and this has been the long road we have travelled to get to where we are now. Along this marathon, dear friends and Customers, you have never failed to give us so much encouragement, so much applause and even some rightful whistles that have helped us improve even more… This is why we want to celebrate our 50th anniversary with all of you. The anniversary of true control of production processes.